What is filter paper made of? What quality requirements do these technical papers meet? For which applications can they be used? Can Hahnemühle develop papers according to individual customer requirements? Answers to these questions are provided by regular ‘in house’ workshops for laboratory traders and customers from industry and research. In addition to our artist papers for painting or printing, Hahnemühle produces papers for laboratory processes such as filtration and separation since 1883 – formerly marketed under the name of Schleicher & Schuell.

Filter paper “Made by Hahnemühle”

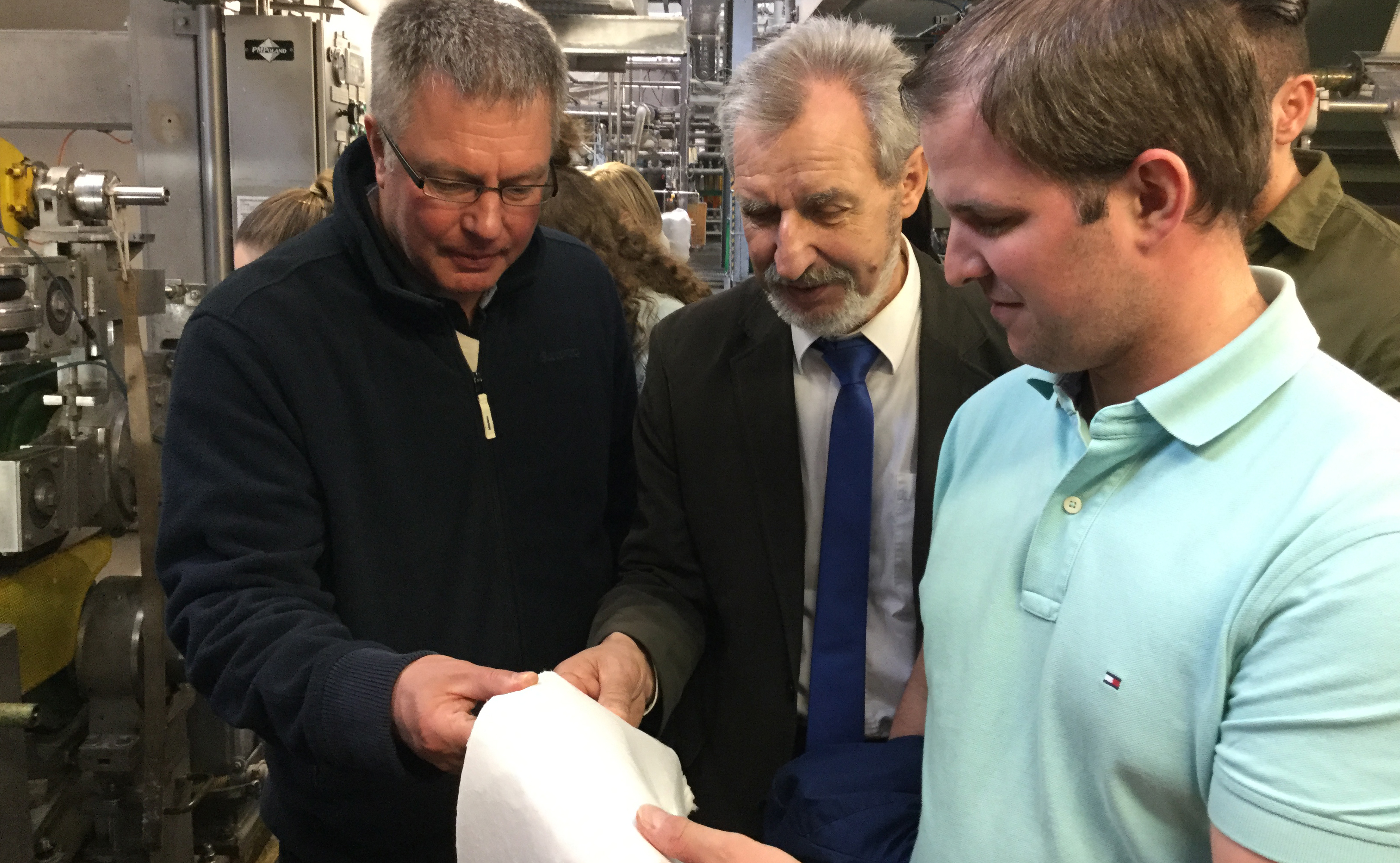

For example, we regularly train members of the Association for Wholesale and Foreign Trade for Nursing and Laboratory Equipment – VGKL shortened. These workshops are a great opportunity for everyone to learn from each other and to network. “In order to ‘dipping’ into the topic of filter papers, we host a guided tour through our production and our in-house quality testing laboratory at the beginning of each training,” says Dr. Horst Rosenbauer, Product Manager Filtration & Separation at Hahnemühle. “The fascination that more than 150 different varieties of filter papers which can be produced on three different paper making machines impresses every visitor. We are able to produce filter papers with a base weight of 50 up to 800 gsm. Many varieties look the same at first sight, but a small difference in a piece of paper makes a decisive advantage in laboratory analysis. This is what we teach in our trainings” adds Dr. Rosenbauer.

With our strict quality controls only the best and reliable papers will be on sale. So we communicate each visitor the tests of incoming raw materials, such as cellulose or cotton linters, through the production-side inspection and the final quality controls of each batch prior market release.

Reliable filter products ensure constant results

Knowledge about the properties of technical papers as well as the easy and effective handling of varieties of papers is essential in laboratory analysis. At the end of March 2017, employees of laboratory traders had been trained at Hahnemühle within the framework of a one-week course called ‘Material properties and fields of application of laboratory consumables’. Hahnemühle hosted 39 new employees of the dealers with the main focus on filter papers and membranes.

The main points of the training program:

- Variety of features and applications of filter papers

- Properties of a reliable filter papers

- Selection of the optimal filter material

- Examples of applications in chemical analysis

Workshop guests finally rated their training with top marks. For us praise and stimulation for the next workshops in the field of filtration papers.

How is the porosity given to the paper?

Hello, Thank you for updating the given post. Every sentence was dripped in knowledge and information, looking forward for something great to come from your site.

Hey,Thank you for posting the above mentioned post. It was a great post. I have picked up a great deal of subjective data and information from it. Searching forward for few more similar contents.

Hi there,

Nice blog. Here I want to add that while manufacturing filter paper, manufacturer should focus on “low ash content”. The lower ash content the higher filter paper quality.

Dear Lab Filter Paper, please check our website for our ashless filter papers.

https://www.hahnemuehle.com/en/filtration/lab-filtration/filter-paper/quantitative-filterpapiere/ashless-filter-papers-for-quantitative-analysis.html

Loved the article!! Just curious, what type of filter paper is used for fabric softener sheets?

Dear Justin,

as far as we know these softener sheets are fabrics. We don´t produce them.